Tagged: Product Challenge

-

AuthorPosts

-

-

Initial Challenge:

Customer is a blacksmith apprentice with a limb difference and inability to grasp with their dominant left arm. We have been asked to develop a low-cost prosthetic that will allow Customer to use blacksmithing tools.

The device must be heat-resistant and able to withstand blacksmithing forces. Ideally, the device will allow for interchangeable tools.

Similar Items:

Nothing open-source to note. See custom product images submitted by Customer.

Summary:

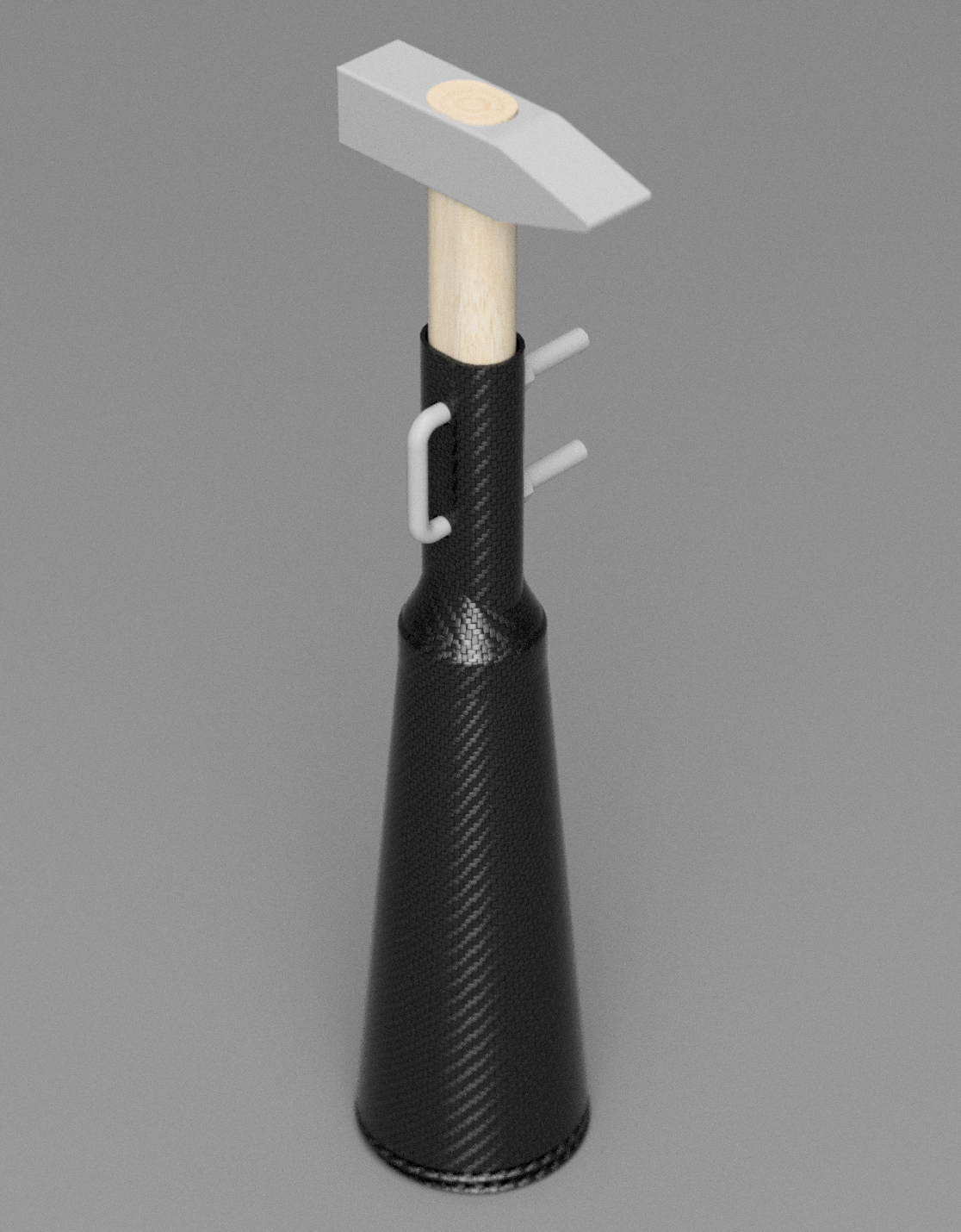

We designed and 3D-printed a thin structure that was then wrapped in carbon fiber mesh coated in thermoset epoxy resin.

2 x 1/4″ holes spaced 4″ apart were drilled into the neck shaft to accommodate a 4″ U-bolt, which will hold tool in place.

Tool must have a custom shaft fit to length and drilled with 2 x 1/4″ holes spaced 4″ apart to accommodate U-bolt.

2 quick-release strap-locks (for electric guitars) were attached to the base to allow for a strap to wrap around the elbow, keeping the device in place when swinging.

The entire structure is wrapped in a leather heat shield.

Adaptive Blacksmithing Tool PrototypeFunctional prototype designed with two parts to allow changing the tool.

Testing the functional prototype.

Rendering of the Final Design

This version allowed a tool with a custom handle to be inserted into the unibody design, with a u-bolt used to secure the tool in place.

Testing the final version.Initial Customer Feedback:

“…For sturdiness, _much_ improved. [Customer] is working on lining the inside with athletic tape to pad it out until it fits snugly over arm.

We couldn’t get the over-the-elbow cuff to work, so I’ve been working on figuring out a more secure setup…and I keep coming back to the old picture of Patrick O’Neill:I’m planning on getting a hinged elbow brace and seeing about getting that fit to the prosthetic – that would mimic the setup that O’Neill had for securing to the arm. For initial fit, I think we can just strap the brace around the prosthetic. I’ll see what the options are for more permanent attachment once I get the brace…

…which bring us to the hammer – I had originally been thinking that [Customer] would be using an eastern-style swing (shoulder and elbow swing while the wrist remains locked/rigid)…but that requires a different alignment for the hammer (almost a right angle to what we have currently). Going back to the picture of O’Neill, the swing style looks to be something different entirely, using almost all shoulder/back in what would (appropriately enough) be called a hammer-fist in martial arts. Think “Hulk Smash!” To get the angle of impact right, I think we’re going to need to shorten the handle length, again, getting closer to O’Neill’s setup. I _think_ that we can do this with the current prosthetic – I’m going to give that a try once we get the brace and padding rigged into place.”

Secondary Customer Feedback and Challenge:

“The new design is great for strength and durability – no notes on that. The hinged elbow brace that I brought looks to work extremely well for keeping the prosthetic attached, but is going to require shortening the prosthetic to avoid pinching inside the elbow joint during flexion (and running into the brace hinges). If we take 3” off of the end of the prosthetic it would fit perfectly. No need for the brace attachments on the existing, either.

The other change gets into the physics of a hammer swing. The hammer is currently mounting with the handle at a 0 degree angle relative to the forearm – if you make a fist, the hammer is extending straight out from your knuckles. Holding a hammer for an eastern style swing (where the wrist remains locked) has it at a 45 degree angle upwards relative to the forearm. That’s the main change that I think we need to make on the prosthetic — angling the mounting point upwards 45 degrees (back of the hammer in the photo below moving up 45º). That would let us take any hammer handle and simply shave it down to fit (and drill holes for the u-bolt).”Download the STL files needed for this project.

-

-

AuthorPosts

- You must be logged in to reply to this topic.

![A one armed blacksmith named Patrick O’Neill using his specially made prosthetic arm. Tottenham, England. November, 1929 [517×802]. : r Blacksmith A one armed blacksmith named Patrick O'Neill using his specially made prosthetic arm. Tottenham, England. November, 1929 [517x802]. : r Blacksmith](https://makers.iltech.org/wp-content/uploads/sites/7/2025/01/A-one-armed-blacksmith-named-Patrick-ONeill-using-his-specially-made-prosthetic-arm.-Tottenham-England.-November-1929-517x802.-r_Blacksmith.avif)